The difference between calcined coke and petroleum coke

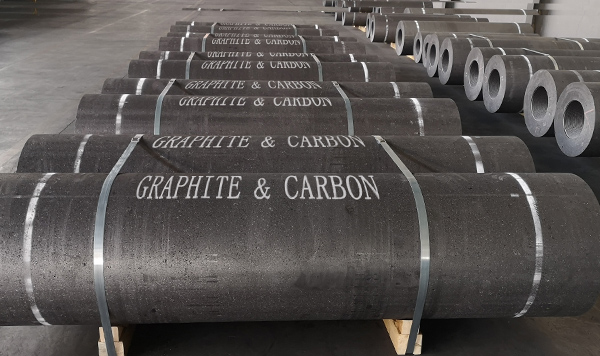

The difference between calcined coke and petroleum coke 1: Appearance Calcined coke: From the appearance, the calcined coke is a black block with irregular shape and different sizes, with strong metallic luster, and the pores of the carbon particles are more transparent after calcining; Petroleum coke: There is not much difference in shape compared to […]

The difference between calcined coke and petroleum coke Read More »