The Vital Importance of Natural Graphite in Modern Technology

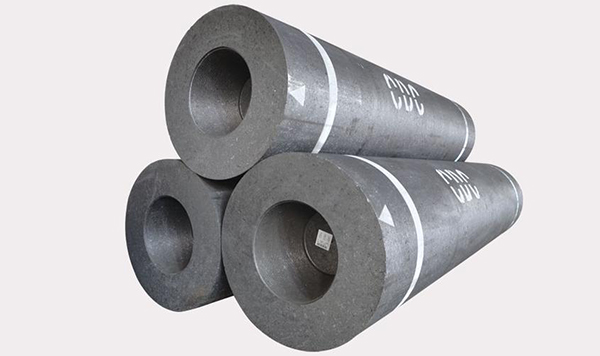

Natural graphite, a unique and versatile form of carbon, is integral to many advanced technologies and industrial processes. As a specialized manufacturer of graphite products, it’s essential to understand and communicate the critical role of natural graphite. This article explores the fundamental properties of natural graphite, its diverse applications, and its future prospects in various […]

The Vital Importance of Natural Graphite in Modern Technology Read More »