Multifaceted Characteristics of Graphite: From Atomic Structure to Industrial Applications

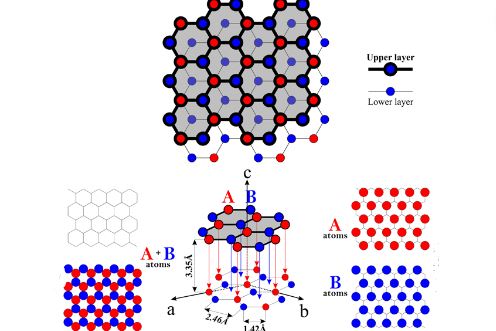

Atomic Configuration and Bonding Characteristics (1) Layered Crystal System Graphite exhibits a unique 2D honeycomb lattice structure. Each carbon atom forms covalent bonds (1.42Å bond length, 120° bond angle) with