UHP HP RP Graphite Electrode 600-700MM for Metallurgical production

Graphite electrode is made from domestic first-class petroleum coke and high quality needle coke and are widely used in electric arc furnaces for the production of alloy steels, metal, and other nonmetallic materials, etc.

Graphite electrode brief introduction

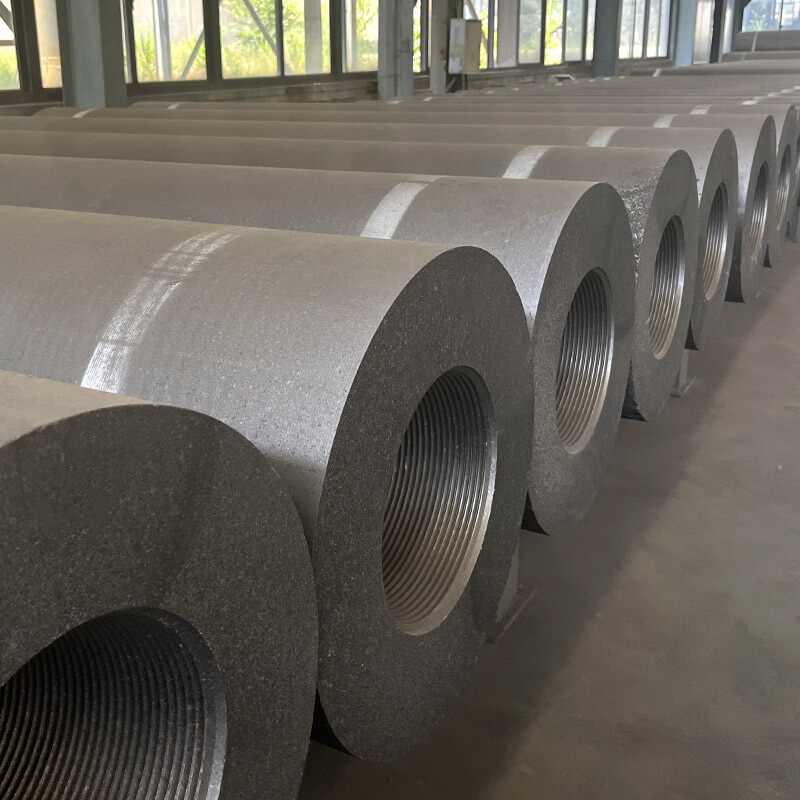

Graphite electrode is made from domestic first-class petroleum coke and high quality needle coke and are widely used in electric arc furnaces for the production of alloy steels, metal, and other nonmetallic materials, etc. The Graphite electrodes include regular power, high power, ultra-high power, and square electrodes. The range of diameters covers from 250mm to 700mm.

Our products have the following characteristics: low electric resistivity, good electrical and thermal conductivity, high oxidation resistance, greater resistance to thermal and mechanical shock, high mechanical strength, and high machining accuracy.

Application

Graphite electrodes are mainly used in electric arc furnace steelmaking, the working principle of graphite electrodes in steel refining involves generating high temperatures through an electric arc, melting the metal at the furnace’s base, and facilitating critical chemical reactions such as decarburization and alloying to produce high-quality steel.

Specifications for BENHONG Graphite electrode

| RP | HP | UHP | |

| Diameter | 75mm-1400mm with lengths of 1000mm-2200mm | 75mm-700mm with lengths of 1000mm-2700mm | 350mm-700mm with lengths of 1600mm-2700mm |

Parameters of ultra-high power Graphite electrodes

| ITEMS | NOMINAL DIAMETER(MM) | ||

| Unit | 600-700 | ||

| Specific resistance | Electrode | μΩ·m | 4.5-5.4 |

| Nipple | 3.0-3.6 | ||

| Transverse strength | Electrode | MPa | ≥10.0 |

| Nipple | ≥24.0 | ||

| Elastic modulus | Electrode | GPa | ≤13.0 |

| Nipple | ≤20.0 | ||

| Ash content | Electrode | % | ≤0.2 |

| Nipple | |||

| Bulk density | Electrode | g/cm3 | 1.68-1.72 |

| Nipple | 1.80-1.86 | ||

| C.T.E | Electrode | 10-6℃ | ≤1.2 |

| Nipple | ≤1.0 | ||

Other attributes

| Place of Origin | Liaoning and Shanxi Province, China |

| Brand Name | BENHONG |

| Color | Black |

| Other name | Graphite Electrode for Electric Arc Furnace,steel,Graphite Electrodes With Nipples Product |

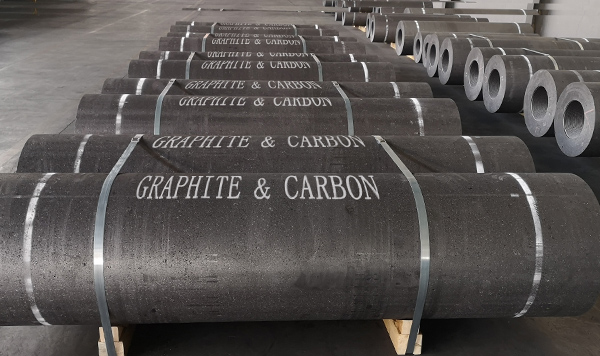

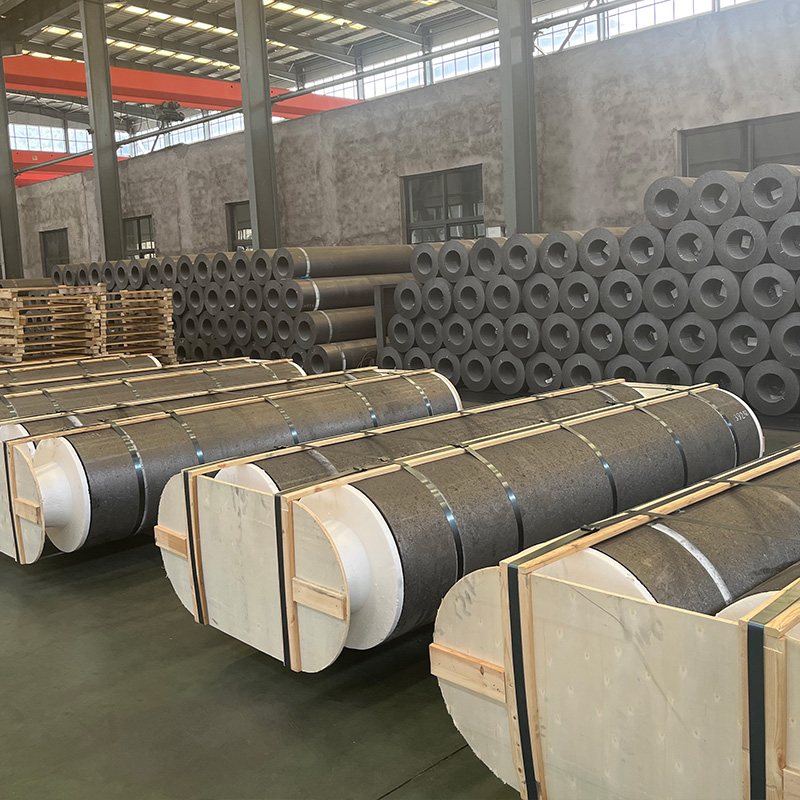

| Packing | Graphite Electrodes are packed on wooden pallets with steel strips |

Graphite electrode recommended joint torque

| Electrode Diameter | Torque | |

| inch | mm | N.m |

| 12 | 300 | 900 |

| 14 | 350 | 1300 |

| 16 | 400 | 1550 |

| 18 | 450 | 1850 |

| 20 | 500 | 2500 |

| 22 | 550 | 3500 |

| 24 | 600 | 4000 |

| 26 | 650 | 5000 |

| 28 | 700 | 6000 |

| 30 | 750 | 7500 |

| 32 | 800 | 9500 |

| Note: Please contact us for any questions. | ||

Attrition rate

The rate at which UHP graphite electrodes are consumed in an EAF depends on the steelmaking or other raw materials used, the grades of steel being produced, and the amount of supplemental (chemical) energy used. EAFs typically consume electrodes at a rate of around 2kg per tonne of steel produced, with some specialty steel applications consuming at a slightly higher rate.

| Specification of electrode | Consumption(kg/ton) | |

| Rough refining | Refining | |

| UHP600mm | 1.2-1.6 | 0.6-0.8 |

| UHP500mm | ||

| UHP400mm | ||

Lead time

| Quantity (tons) | 1-5000 | >5000 |

| Lead time (days) | 15 | To be negotiated |

Packing,protection and safe transportation

About us

BENHONG is a professional manufacturer, specializing in the field of graphite electrodes. With various products, the specifications of graphite electrode range from 75 mm to 700 mm in diameter. Our graphite electrodes have various specifications, These products always have three types of lengths, including 1800 mm, 2100 mm and 2400mm. If user has special requirements, please contact us.

1.30 years of production experience has convinced us that this is our careers, not just a business.

2.We have all the certificates needed in the field:ISO/SGS/MSDS.

3.Our team is honest, united and has a high service spirit.

4.We have establaished cooperation with Saudi Arabia, Iran,India, Turkey, Brazil, Russia and other countries.

5.Customer as the core of the complete after-sales service.

6.The repeat purchase rate exceedns 92%.